Description

Energy management – reduce your costs of energies by up to 25%

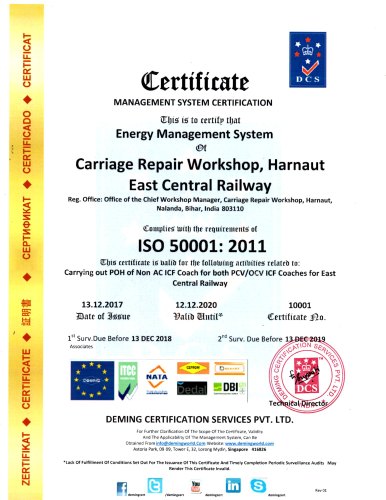

New standard EN ISO 50001:2011 – energy management system. Due to the growing costs of energies and as a result of searching for a new solution within industry a new standard was introduced, focusing on energy management with the objective to reduce costs of companies and overall CO2emissions.

Potential of savings

Direct consumption of machines. Within industrial production an important source of savings consists of optimising energy consumption by production lines, machines and various other equipment. We focus on whether various machines and equipment are not running without use, whether their output is optimised, and whether they are properly adjusted.

Production technology. Another factor influencing energy consumption is optimisation of technological procedures which means that the same objective (namely a product of identical quality) can be achieved by changing the technological procedure with the objective of saving energies. This does not necessarily involve only the technological procedure itself but work organisation on shifts may be involved as well.

Energy consumption not directly related to production. Insufficient thermal insulation, lighting system, obsolete ventilation, inefficiently arranged places of work and other drawbacks within auxiliary processes are another potential source of savings.

Attitude of employees. Training and incentives in favour of employees in order to support meaningful savings provides companies with another positive effect when you consider all the invoices covering energy consumptions.

How to proceed…

Analysis of the initial state. The first step is to find out what the consumption of energy is during various states of operation, shifts and seasons. If it is not entirely detectable, then invest in measuring and monitoring equipment and subsequently analyse the consumption of energy according to individual operations, equipment, buildings. Then create a system of records, which will serve for subsequent monitoring.

Proposals for savings. Within the scope of energy policies, determining the organisational measures and possibly arising investments would lead to a decrease among the greatest “consumers”, whether it concern debugging a production line, replacing equipment, organising shifts, relocating or heat cladding buildings.

Implementation of measures. They can be used independently or (which is what we recommend) used in integration with other standards of modern management systems, particularly on the basis of ISO 14001, ISO 9001, OHSAS 18001 standards, which can cover the complex management system according to type, size and field of business. Subsequently, a comparison should be conducted with the initial state, whether or not only savings have occurred but also whether other parameters have worsened in the field of quality production or company economics.

External audit. An audit performed by an independent side can contribute to further energy savings thanks to experience and an objective view.

Our approach

Energy policy (3.2) The basic element of the entire system, which has to include the status of company management’s commitment to energy management. The energy policy determines the long-term direction of the company. It affects the future company economics. Informally established energy policies lead to future savings in not only energy but also investment funds.

Additional Information:

- Pay Mode Terms: T/T (Bank Transfer),Western Union

Reviews

There are no reviews yet.