Development of recycled materials

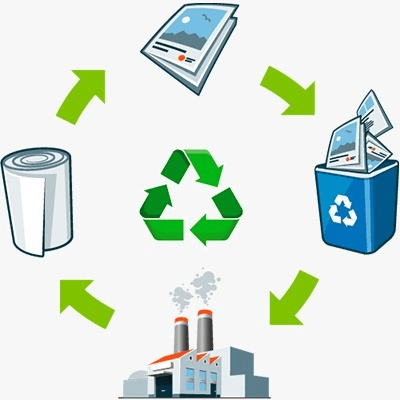

The development of recycled materials is an essential aspect of sustainable resource management and environmental conservation. Recycling helps reduce the consumption of raw materials, energy usage, and the generation of waste. Here are some key points in the development of recycled materials:

- Research and Innovation:

- Ongoing research is crucial for identifying new materials that can be recycled or developing better recycling processes for existing materials.

- Innovations in material science play a vital role in creating recycled materials with properties comparable to or even better than their virgin counterparts.

- Collection and Sorting:

- Efficient collection and sorting systems are necessary to gather recyclable materials from various sources.

- Advanced technologies, such as robotics and artificial intelligence, can enhance the speed and accuracy of sorting processes.

- Recycling Technologies:

- Continued improvement and adoption of recycling technologies are essential. This includes mechanical recycling, chemical recycling, and biological recycling.

- Chemical recycling, in particular, has gained attention for its potential to break down plastics into their original building blocks for reuse.

- Circular Economy:

- The concept of a circular economy promotes the continuous use of resources through recycling, remanufacturing, and reuse.

- Companies and governments are increasingly adopting circular economy principles to minimize waste and maximize resource efficiency.

- Market Demand:

- Increased demand for recycled materials helps drive investment and innovation in the recycling industry.

- Consumer awareness and preferences for sustainable products contribute to market demand for recycled materials.

- Government Policies and Regulations:

- Supportive policies and regulations can encourage businesses to use recycled materials and invest in recycling infrastructure.

- Extended Producer Responsibility (EPR) programs shift the responsibility for end-of-life product management to manufacturers, motivating them to use recyclable materials.

- Public Awareness and Education:

- Educating the public about the importance of recycling and proper waste disposal is critical for increasing the supply of recyclable materials.

- Public awareness campaigns can also help reduce contamination in recycling streams.

- Collaboration:

- Collaboration among government bodies, industry players, and non-profit organizations is essential for creating a comprehensive and effective recycling ecosystem.

- Partnerships can foster information sharing, technological advancements, and the development of best practices.

- Investment in Infrastructure:

- Adequate recycling infrastructure, including collection systems, recycling facilities, and waste-to-energy plants, is necessary for the efficient processing of recycled materials.

- Life Cycle Assessments:

- Conducting life cycle assessments helps evaluate the environmental impact of materials throughout their entire life cycle, guiding decisions on material selection and recycling processes.

The development of recycled materials is an ongoing process that requires collaboration, innovation, and a commitment to sustainable practices from individuals, businesses, and governments alike.

What is required Development of recycled materials

The development of recycled materials involves a multifaceted approach that requires the collaboration of various stakeholders, technological advancements, and supportive policies. Here are key elements required for the development of recycled materials:

- Research and Development:

- Ongoing research to identify new materials that can be recycled effectively.

- Development of innovative technologies for recycling processes, including improvements in sorting, cleaning, and transforming recycled materials.

- Infrastructure Investment:

- Investment in recycling infrastructure, including collection systems, recycling facilities, and waste-to-energy plants.

- Implementation of advanced technologies for efficient and cost-effective recycling.

- Technological Advancements:

- Continuous improvement and adoption of recycling technologies, such as chemical recycling, to increase the types of materials that can be recycled and enhance the quality of recycled products.

- Circular Economy Practices:

- Adoption of circular economy principles, which focus on designing products for durability, reparability, and recyclability.

- Integration of closed-loop systems that promote the reuse and recycling of materials.

- Government Policies and Regulations:

- Implementation of supportive policies and regulations that encourage recycling and the use of recycled materials.

- Extended Producer Responsibility (EPR) programs that hold manufacturers accountable for the end-of-life management of their products.

- Market Demand:

- Creation of market demand for recycled materials through consumer education and awareness.

- Incentives for businesses to use recycled materials in their products.

- Collaboration and Partnerships:

- Collaboration among government agencies, industry players, non-profit organizations, and research institutions to share knowledge and resources.

- Partnerships between manufacturers and recyclers to streamline the supply chain for recycled materials.

- Education and Public Awareness:

- Public education campaigns to raise awareness about the importance of recycling and proper waste disposal.

- Training programs for waste management personnel and recycling facility workers.

- Quality Standards:

- Establishment of quality standards for recycled materials to ensure they meet the required specifications for various applications.

- Certification programs to verify the authenticity and quality of recycled products.

- Waste Reduction Strategies:

- Implementation of strategies to reduce overall waste generation, including source reduction, product redesign, and the promotion of reusable products.

- Incentives and Subsidies:

- Financial incentives or subsidies to encourage businesses to invest in recycling technologies and use recycled materials.

- Tax breaks for companies that demonstrate a commitment to sustainable practices.

- International Cooperation:

- Collaboration at the international level to address global challenges related to recycling, including the development of common standards and sharing best practices.

- Life Cycle Assessments:

- Conducting life cycle assessments to evaluate the environmental impact of materials and guide decision-making in material selection and recycling processes.

The successful development of recycled materials requires a comprehensive and integrated approach that considers environmental, economic, and social factors. It involves a collective effort from governments, industries, communities, and individuals to create a sustainable and circular economy.

Who is required Development of recycled materials

The development of recycled materials involves the efforts and contributions of various stakeholders across different sectors. Here are key participants required for the development of recycled materials:

- Government Agencies:

- Enactment and enforcement of policies and regulations that support recycling initiatives.

- Implementation of Extended Producer Responsibility (EPR) programs to hold manufacturers accountable for the end-of-life management of their products.

- Investment in recycling infrastructure and research and development.

- Research and Development Institutions:

- Conducting research to identify new recyclable materials and improve existing recycling technologies.

- Collaborating with industry partners to innovate and optimize recycling processes.

- Recycling Industry:

- Operation and maintenance of recycling facilities.

- Collection and processing of recyclable materials.

- Investment in advanced recycling technologies and infrastructure.

- Manufacturers and Businesses:

- Incorporating recycled materials into their products.

- Designing products with recycling in mind, considering factors like ease of disassembly and material separability.

- Supporting and investing in recycling initiatives and technologies.

- Consumers:

- Proper disposal of recyclable materials in designated bins.

- Choosing products made from recycled materials.

- Participating in community recycling programs.

- Non-Governmental Organizations (NGOs):

- Advocating for sustainable practices and policies.

- Educating the public about the benefits of recycling and the importance of waste reduction.

- Collaborating with businesses and governments to promote responsible waste management.

- Waste Management Companies:

- Collection and transportation of recyclable materials.

- Sorting and processing of collected materials in recycling facilities.

- Collaboration with municipalities and businesses to improve waste management practices.

- Educational Institutions:

- Providing training programs and courses related to recycling and sustainable practices.

- Conducting research to improve recycling technologies and processes.

- International Organizations:

- Facilitating collaboration and information exchange among countries.

- Setting international standards for recycled materials and waste management.

- Community Organizations:

- Engaging local communities in recycling initiatives.

- Organizing clean-up and recycling events.

- Promoting awareness and education on the importance of recycling.

- Investors and Financial Institutions:

- Providing funding for research and development in recycling technologies.

- Investing in businesses that prioritize sustainability and the use of recycled materials.

- Standards Organizations:

- Developing and maintaining quality standards for recycled materials.

- Certifying products made from recycled materials to ensure their authenticity and quality.

- Technology Providers:

- Developing and supplying innovative technologies for sorting, cleaning, and processing recycled materials.

- Collaborating with recycling facilities to implement and improve technology solutions.

The development of recycled materials is a collaborative effort that requires the active involvement and commitment of these stakeholders working together to create a sustainable and circular economy.

When is required Development of recycled materials

The development of recycled materials is an ongoing and continuous process that is required at various stages of the material lifecycle. Here are key instances when the development of recycled materials is crucial:

- Product Design and Manufacturing:

- Incorporating recycled materials into the design phase of products.

- Ensuring that products are manufactured using materials that can be easily recycled.

- Waste Collection and Sorting:

- Implementing efficient waste collection and sorting systems to gather recyclable materials.

- Developing technologies and processes for effective and accurate sorting of recyclables.

- Recycling Facilities and Processes:

- Ongoing research and development in recycling technologies to improve efficiency and effectiveness.

- Continuous innovation to expand the range of materials that can be recycled.

- Investment in infrastructure for recycling facilities.

- Consumer Behavior:

- Educating and raising awareness among consumers about the importance of recycling.

- Encouraging consumers to choose products made from recycled materials.

- Government Policies and Regulations:

- Implementing and updating policies and regulations that promote recycling.

- Introducing Extended Producer Responsibility (EPR) programs to ensure manufacturers contribute to the recycling process.

- Market Demand:

- Creating and sustaining demand for recycled materials in the market.

- Encouraging businesses to invest in and use recycled materials in their products.

- Technological Advancements:

- Embracing and adopting new technologies that enhance recycling processes.

- Investing in research and development to create advanced recycling methods.

- International Collaboration:

- Collaborating with other countries and international organizations to share best practices and address global challenges related to recycling.

- Community Engagement:

- Engaging communities in recycling initiatives and promoting responsible waste management.

- Conducting awareness campaigns to involve the public in recycling efforts.

- Crisis Response:

- Responding to environmental crises, such as pollution or resource scarcity, by emphasizing the importance of recycling and developing solutions.

- Innovation and Emerging Technologies:

- Seizing opportunities presented by emerging technologies, such as artificial intelligence and robotics, to improve recycling processes.

- Environmental Considerations:

- Considering the environmental impact of materials throughout their lifecycle, from extraction to disposal, and promoting the use of recycled materials as an eco-friendly alternative.

In summary, the development of recycled materials is a continuous and interconnected process that involves efforts from various stakeholders at different stages of the material lifecycle. It is essential to integrate sustainable practices into product design, manufacturing, consumption, and waste management to create a circular and environmentally friendly economy.

Where is required Development of recycled materials

The development of recycled materials is required in various sectors and locations throughout the world. Here are key areas where the development of recycled materials is crucial:

- Manufacturing Industries:

- Incorporating recycled materials into the production of goods and products.

- Implementing sustainable and circular design principles in manufacturing processes.

- Construction and Building Materials:

- Using recycled materials in construction, such as recycled concrete, steel, or plastic.

- Developing innovative building materials made from recycled components.

- Packaging Industry:

- Utilizing recycled materials for packaging to reduce the environmental impact of packaging waste.

- Developing eco-friendly packaging alternatives.

- Consumer Goods and Retail:

- Encouraging the use of recycled materials in the production of consumer goods.

- Creating awareness among consumers about the importance of choosing products made from recycled materials.

- Waste Management Facilities:

- Upgrading and investing in recycling facilities for efficient sorting and processing of recyclable materials.

- Implementing advanced technologies to improve recycling processes.

- Government and Municipalities:

- Enforcing and updating recycling policies and regulations.

- Investing in recycling infrastructure and promoting waste reduction initiatives.

- Educational Institutions:

- Incorporating education about recycling and sustainability into school curricula.

- Conducting research on new recycling technologies and processes.

- Technology and Innovation Hubs:

- Supporting research and development in innovative recycling technologies.

- Fostering collaboration between technology providers, researchers, and industries.

- International Organizations:

- Facilitating collaboration and information exchange on a global scale.

- Setting international standards for recycled materials.

- Community and Local Initiatives:

- Engaging local communities in recycling programs and clean-up events.

- Establishing community recycling centers and drop-off points.

- Environmental Conservation Areas:

- Implementing sustainable practices in protected areas and natural habitats.

- Using recycled materials in environmental restoration and conservation projects.

- Fashion and Textile Industry:

- Promoting the use of recycled fibers and fabrics in the fashion industry.

- Encouraging sustainable and circular fashion practices.

- Transportation and Automotive Industry:

- Incorporating recycled materials into vehicle manufacturing.

- Exploring eco-friendly alternatives for automotive components.

- Food and Beverage Industry:

- Utilizing recycled materials in packaging for food and beverage products.

- Implementing sustainable practices in food packaging and distribution.

- Healthcare Sector:

- Exploring ways to reduce medical waste through recycling and sustainable practices.

- Adopting eco-friendly materials in healthcare product packaging.

In essence, the development of recycled materials is needed across a wide range of industries, communities, and sectors globally. It requires a collective effort from businesses, governments, research institutions, and individuals to create a sustainable and circular economy.

How is required Development of recycled materials

The development of recycled materials involves a combination of strategies, technologies, policies, and collaborative efforts across various sectors. Here’s how the development of recycled materials is typically required:

- Research and Development:

- Material Innovation: Invest in research to identify new materials that can be recycled effectively and develop innovative materials that have desirable properties for various applications.

- Process Optimization: Continuously improve and optimize recycling processes to enhance efficiency, reduce energy consumption, and minimize environmental impact.

- Technological Advancements:

- Advanced Sorting Technologies: Implement advanced technologies, such as robotics and artificial intelligence, for efficient and accurate sorting of recyclable materials.

- Chemical Recycling: Invest in and adopt chemical recycling technologies that can break down materials into their original components for reuse.

- Infrastructure Investment:

- Recycling Facilities: Invest in the development and maintenance of recycling facilities, including sorting centers, material recovery facilities, and processing plants.

- Collection Systems: Improve and expand waste collection systems to ensure the efficient gathering of recyclable materials.

- Circular Economy Practices:

- Product Design: Encourage product design with a focus on durability, reparability, and recyclability, embracing the principles of a circular economy.

- Closed-Loop Systems: Establish closed-loop systems where materials are continuously recycled and reused within the production cycle.

- Government Policies and Regulations:

- Legislation: Enact and enforce policies and regulations that support recycling efforts and create incentives for businesses to use recycled materials.

- Extended Producer Responsibility (EPR): Implement EPR programs to hold manufacturers responsible for the end-of-life management of their products.

- Market Demand:

- Consumer Awareness: Educate consumers about the benefits of recycled materials and create awareness to drive demand for products made from recycled content.

- Business Incentives: Provide incentives for businesses to incorporate recycled materials into their products, fostering a market for recycled materials.

- Collaboration:

- Public-Private Partnerships: Foster collaboration between government agencies, businesses, non-profit organizations, and research institutions to share knowledge, resources, and expertise.

- Industry Collaboration: Encourage collaboration within industries to develop common standards, share best practices, and address challenges collectively.

- Education and Training:

- Workforce Development: Provide training programs for workers in the waste management and recycling industry.

- Public Education: Educate the public about proper recycling practices, the environmental benefits of recycling, and the importance of waste reduction.

- Quality Standards:

- Certification Programs: Establish certification programs to verify the authenticity and quality of recycled materials and products.

- Standardization: Develop and adhere to quality standards for recycled materials to ensure consistency and reliability.

- Innovation Hubs:

- Research and Development Centers: Establish innovation hubs and centers that focus on developing and scaling up recycling technologies.

- Start-up Support: Encourage and support start-ups and entrepreneurs working on novel recycling solutions.

- Financial Support:

- Government Grants and Subsidies: Provide financial support, grants, and subsidies to encourage investment in recycling infrastructure and technologies.

- Private Investment: Attract private investment in recycling ventures through financial incentives.

- Life Cycle Assessments:

- Environmental Impact Assessment: Conduct life cycle assessments to evaluate the environmental impact of materials and guide decision-making in material selection and recycling processes.

The development of recycled materials requires a holistic and coordinated approach, involving collaboration between government bodies, businesses, research institutions, and the public. By addressing technological, policy, and societal aspects, a sustainable and effective recycling ecosystem can be established.

Case Study on Development of recycled materials

Let’s consider a hypothetical case study on the development of recycled materials in the construction industry:

Case Study: Sustainable Construction with Recycled Materials

Background: A construction company, EcoBuild Innovations, specializes in sustainable and environmentally friendly building practices. Recognizing the importance of reducing the environmental impact of construction projects, the company decided to embark on a journey to develop and implement recycled materials in its construction projects.

Objectives:

- Reduce Environmental Footprint: Minimize the consumption of raw materials and decrease the overall environmental impact of construction activities.

- Incorporate Recycled Content: Integrate recycled materials into construction processes and products to contribute to a circular economy.

- Maintain Performance Standards: Ensure that the use of recycled materials does not compromise the quality or safety of construction projects.

Implementation:

- Research and Development:

- Collaborated with material scientists and researchers to identify suitable recycled materials with properties conducive to construction applications.

- Investigated innovative construction methods that could leverage recycled materials.

- Recycled Concrete and Aggregates:

- Explored the use of recycled concrete aggregates (RCA) made from crushed concrete debris for use in new construction.

- Conducted trials to determine the optimal mix ratios for recycled concrete while maintaining structural integrity.

- Recycled Plastic Composite Materials:

- Developed composite materials using recycled plastics for non-structural elements like facades, decking, and interior finishes.

- Ensured the performance, durability, and aesthetic appeal of these recycled plastic composites.

- Waste Management and Collection:

- Collaborated with waste management companies to source construction waste for recycling.

- Established a dedicated waste collection system at construction sites to separate and collect recyclable materials.

- Quality Standards and Testing:

- Worked with industry experts to establish quality standards for recycled construction materials.

- Conducted rigorous testing to verify the performance and safety of recycled materials.

- Community Engagement:

- Educated construction teams and local communities about the benefits of using recycled materials in construction.

- Engaged with suppliers and subcontractors to create a network supportive of sustainable practices.

- Regulatory Compliance:

- Stayed informed about relevant regulations and certifications related to the use of recycled materials in construction.

- Ensured compliance with building codes and standards.

Results:

- Successful Integration of Recycled Materials:

- Implemented recycled concrete aggregates in the construction of foundations and pavements, reducing the demand for virgin aggregates.

- Introduced recycled plastic composite materials in exterior elements, contributing to the reduction of plastic waste.

- Positive Environmental Impact:

- Reduced the carbon footprint of construction projects by lowering the need for energy-intensive processes in the production of new materials.

- Decreased the amount of construction waste sent to landfills, aligning with waste reduction goals.

- Maintained Construction Quality:

- Verified that structures and elements made with recycled materials met or exceeded industry performance standards.

- Demonstrated that the use of recycled materials did not compromise the durability or safety of the constructed buildings.

- Cost-Efficiency and Market Recognition:

- Discovered that the use of recycled materials was cost-competitive, considering long-term environmental and social benefits.

- Gained positive recognition in the market for environmentally conscious construction practices, attracting clients who prioritize sustainability.

- Scalability and Replicability:

- Developed a model for incorporating recycled materials that could be replicated in various construction projects.

- Shared best practices with other construction companies to encourage industry-wide adoption of sustainable building materials.

Conclusion: EcoBuild Innovations successfully demonstrated the feasibility and advantages of incorporating recycled materials into construction practices. The case study serves as an example of how a construction company can contribute to environmental sustainability while maintaining construction quality and meeting industry standards. Through research, collaboration, and innovation, EcoBuild Innovations showcased that the development of recycled materials is not only feasible but also economically viable and environmentally responsible.

White Paper on Development of recycled materials

Title: Advancing Sustainable Development through Recycled Materials: A Comprehensive White Paper

Abstract: This white paper explores the critical role of recycled materials in fostering sustainable development across industries. It provides an in-depth analysis of the challenges, opportunities, and best practices associated with the development and integration of recycled materials. By examining case studies, technological advancements, and policy considerations, this document aims to guide stakeholders in creating a more circular and resource-efficient economy.

Table of Contents:

- Introduction

- Overview of the importance of recycled materials in sustainable development.

- Rationale for promoting the use of recycled materials across industries.

- Current State of Recycling

- Statistical overview of global recycling rates.

- Major challenges in the recycling industry.

- Environmental and Economic Benefits

- Reduction of carbon footprint through the use of recycled materials.

- Economic advantages, including cost savings and job creation.

- Technological Advancements

- Innovations in recycling technologies.

- Emerging trends in material science for developing recyclable and biodegradable materials.

- Case Studies

- In-depth analysis of successful initiatives in different industries (e.g., packaging, construction, manufacturing) that emphasize the use of recycled materials.

- Lessons learned and best practices from notable case studies.

- Policy and Regulatory Frameworks

- Overview of global policies promoting recycling and sustainable material use.

- Recommendations for strengthening regulatory frameworks and implementing Extended Producer Responsibility (EPR) programs.

- Market Demand and Consumer Behavior

- The role of consumer preferences in driving demand for products made from recycled materials.

- Strategies for businesses to capitalize on market demand for sustainable products.

- Collaboration and Partnerships

- Importance of collaboration among government bodies, businesses, NGOs, and research institutions.

- Successful examples of collaborative efforts to promote the development and utilization of recycled materials.

- Education and Awareness

- The significance of public awareness campaigns in promoting responsible waste management.

- Integrating recycling education into school curricula.

- Investment and Funding

- The role of public and private investment in supporting research, development, and infrastructure for recycled materials.

- Financial incentives for businesses investing in recycling initiatives.

- Challenges and Potential Solutions

- Identifying common challenges in the development of recycled materials.

- Proposed solutions and mitigation strategies.

- Future Outlook

- Predictions for the future of recycled materials development.

- Areas for further research and innovation.

Conclusion: This white paper concludes by emphasizing the urgency of advancing the development of recycled materials for a sustainable and circular economy. It calls for collective action from governments, industries, and individuals to prioritize recycling efforts, invest in research and technology, and create an environment that fosters the widespread adoption of recycled materials. The integration of recycled materials is not only an environmental imperative but also a pathway to a more resilient and resource-efficient future.

Industrial Application on Development of recycled materials

Title: Transformative Innovations: Industrial Applications of Recycled Materials

Abstract: This report delves into the industrial landscape, exploring how the development and integration of recycled materials are revolutionizing manufacturing processes, reducing environmental impact, and fostering sustainable practices. Through a detailed examination of various industries, this report highlights successful industrial applications, innovative technologies, and the resulting economic and environmental benefits.

Table of Contents:

- Introduction

- Overview of the significance of recycled materials in industrial applications.

- The economic and environmental motivations for industries to adopt recycled materials.

- Automotive Industry

- Utilization of recycled plastics and metals in vehicle manufacturing.

- Case studies on successful integration and performance of recycled materials in automotive components.

- Construction and Building Materials

- Adoption of recycled concrete, aggregates, and composites in construction projects.

- Advantages, challenges, and key considerations in using recycled materials in the construction industry.

- Packaging and Consumer Goods

- Incorporation of recycled materials in packaging design and production.

- The role of recycled content in meeting consumer demands for sustainable products.

- Electronics Manufacturing

- Integration of recycled metals and plastics in electronic devices.

- Innovations in electronic waste (e-waste) recycling and circular economy practices.

- Textile and Fashion Industry

- Trends and challenges in using recycled fibers in textile manufacturing.

- Sustainable practices in the fashion industry, including clothing made from recycled materials.

- Food and Beverage Packaging

- Use of recycled materials in food packaging.

- Technological advancements and innovations in sustainable packaging solutions.

- Aerospace Industry

- Exploration of recycled materials in aerospace manufacturing.

- Case studies on the successful application of recycled materials in aircraft components.

- Energy Sector

- The role of recycled materials in renewable energy technologies.

- Innovations in the use of recycled materials in solar panels, wind turbines, and energy storage systems.

- Challenges and Solutions

- Common challenges faced by industries in adopting recycled materials.

- Technological, policy, and collaborative solutions to overcome these challenges.

- Economic and Environmental Impacts

- Quantifying the economic benefits of using recycled materials in industrial processes.

- Assessing the environmental impact and carbon footprint reduction achieved through the adoption of recycled materials.

- Future Trends and Outlook

- Emerging technologies and materials in industrial recycling.

- Predictions for the future of recycled materials in industrial applications.

Conclusion: This report concludes by emphasizing the transformative impact of recycled materials on various industries, promoting sustainable development, and mitigating environmental concerns. It calls for continued research, collaboration, and innovation to accelerate the adoption of recycled materials across industries, contributing to a more sustainable and circular industrial ecosystem.